In today’s competitive hospitality market, finding reliable restaurant supplies furniture directly from factories has become one of the smartest ways for restaurant owners and designers to balance cost, quality, and customization.

Whether you’re furnishing a cozy café or a full-service restaurant chain, direct sourcing allows you to cut out middlemen, control your design process, and secure better pricing. But it’s not as simple as finding a factory on Google — the key lies in understanding the process, evaluating manufacturers, and communicating like a pro.

Let’s break down how to source commercial restaurant supplies furniture directly from a factory in 2025 — step by step.

1. Understand What “Factory Direct” Really Means

When we say “factory direct,” we’re referring to purchasing commercial-grade restaurant furniture directly from the manufacturer — not through wholesalers or trading companies.

This approach gives you several major advantages:

- 💰 Lower pricing (typically 15–30% less)

- 🎨 Customization freedom for size, color, or materials

- ⚙️ Faster feedback loop for prototyping and adjustments

- 🤝 Closer quality control during production

However, factory-direct sourcing also comes with responsibilities — you’ll need to handle logistics, compliance checks, and sometimes language or time zone barriers.

2. Identify the Right Type of Factory

Not all furniture factories are created equal. Some specialize in wood furniture, others in metal and upholstery, while a few integrate complete restaurant seating systems (booths, tables, chairs, bar stools).

When sourcing restaurant supplies furniture, focus on factories that:

- Have 10+ years in hospitality projects

- Offer custom OEM & ODM service

- Provide commercial-grade test reports (ASTM, ANSI/BIFMA, EN16139)

- Own in-house upholstery, metal, and carpentry workshops

🧭 Pro Tip:

Use trade platforms like Alibaba Verified Suppliers, Made-in-China, or Global Sources, but always confirm the factory’s real business license and visit or video-tour their facility before placing large orders.

3. Clarify Your Product Specifications

Before you contact a factory, have your requirements clear and documented.

Factories value clients who know what they want — it speeds up quoting and avoids mistakes.

Key details to include:

- Product type (chairs, tables, booths, outdoor sets)

- Materials (solid wood, metal, fabric, HPL, marble-look)

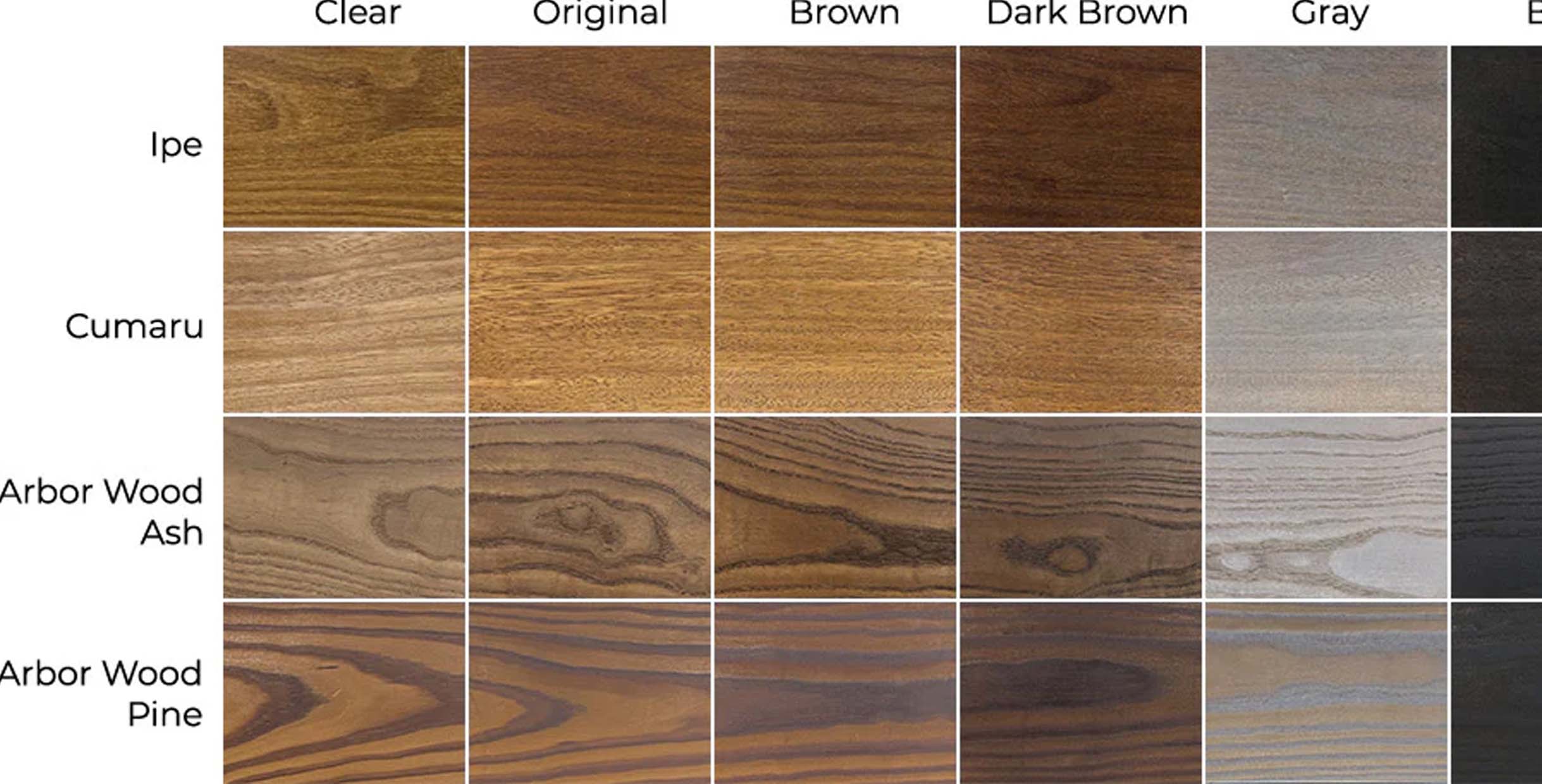

- Finishes (powder coating, veneer, paint color code)

- Dimensions or CAD drawings

- Target quantity and delivery schedule

4. Evaluate Factory Capabilities

Here’s what to look for when assessing whether a manufacturer can meet your needs:

| Evaluation Area | What to Check | Why It Matters |

|---|---|---|

| Production Capacity | Monthly output & main clients | Ensures timely delivery |

| Material Control | Source of wood/metal & certificates | Prevents quality inconsistency |

| Customization Ability | CNC, laser cutting, upholstery workshop | Enables precise design |

| QC Process | In-house inspection, third-party checks | Guarantees quality |

| Export Experience | Shipping documents, Incoterms familiarity | Reduces customs risk |

5. Compare Pricing Transparently

When getting quotations, make sure you’re comparing apples to apples.

Two factories may quote vastly different prices — not because one is cheating, but because they may be using different materials or finishes.

📊 Example Price Comparison (2025 Average FOB Pricing)

| Product Type | Material | Estimated Price (USD/Unit) | MOQ |

|---|---|---|---|

| Dining Chair | Metal Frame + PU Leather | $45–$65 | 50 pcs |

| Restaurant Table | HPL Top + Iron Base | $90–$130 | 20 sets |

| Booth Seating | Wood + Fabric Upholstery | $220–$350 | 10 pcs |

| Bar Stool | Solid Wood + Steel | $60–$90 | 30 pcs |

💡 Tip: Avoid extremely low quotes. Quality shortcuts often appear later — in weak welds, unstable tables, or fading finishes.

6. Choose the Right Materials

Your choice of materials directly affects durability and maintenance.

Below is a comparison of the most common materials used in restaurant supplies furniture.

📘 Table: Material Comparison for Restaurant Furniture

| Material | Durability | Maintenance | Appearance | Cost |

|---|---|---|---|---|

| Solid Wood (Oak, Beech) | ★★★★★ | Medium | Natural, timeless | $$$ |

| Metal (Steel, Aluminum) | ★★★★☆ | Low | Industrial, modern | $$ |

| Laminate / HPL | ★★★★☆ | Low | Customizable patterns | $ |

| Upholstery (PU, Fabric) | ★★★☆☆ | Medium | Soft, comfortable | $$ |

| Rattan / Wicker (Outdoor) | ★★★☆☆ | Low | Casual, rustic | $$ |

7. Manage Logistics and Shipping

Once production is complete, factories can assist with logistics — but you decide the Incoterm (e.g., EXW, FOB, CIF).

Common Shipping Options:

- FOB (Free on Board) – Factory handles export paperwork; you manage ocean freight.

- CIF (Cost, Insurance, Freight) – Factory arranges delivery to your nearest port.

- DDP (Delivered Duty Paid) – Door-to-door delivery (more costly, most convenient).

📦 For fragile items like marble tables, ensure:

- Thick foam packaging

- Wooden crate reinforcement

- Palletized loading for stability

8. Quality Control & Inspection

Before shipment, always perform a final inspection — either yourself or through a third party like SGS, BV, or TUV.

Checklist:

- Check joints and welds for strength

- Confirm finishes match samples

- Test stability and balance

- Verify packaging and labeling

It’s worth the extra $200–$400 inspection cost to prevent expensive rework later.

9. Sustainability and Certifications

In 2025, eco-conscious consumers care where their dining furniture comes from.

Factories with FSC, ISO14001, or CARB-compliant certifications demonstrate sustainable manufacturing.

Sustainable furniture not only boosts your brand image but can also attract green-minded guests — a key differentiator in competitive hospitality markets.

10. Build Long-Term Supplier Relationships

Factories value repeat customers.

When you maintain communication and provide clear feedback, manufacturers prioritize your orders and offer better rates.

Strong relationships can lead to:

- Faster lead times

- Custom branding privileges

- Exclusive design collaborations

Think of it not as a one-time purchase — but as building your supply chain advantage.

💡 Quick Recap: Steps to Source Restaurant Supplies Furniture from Factory

| Step | Action | Key Outcome |

|---|---|---|

| 1 | Research verified factories | Identify trustworthy suppliers |

| 2 | Define specifications | Speed up quotation |

| 3 | Compare quotes | Balance cost and quality |

| 4 | Confirm samples | Validate design and durability |

| 5 | Inspect before shipment | Ensure no surprises |

| 6 | Maintain communication | Build long-term partnership |

🔍 FAQs

Q1: What’s the minimum order quantity (MOQ) for most factories?

A: Usually 20–50 pieces per model, but negotiable for new designs.

Q2: Can factories handle full restaurant layouts?

A: Yes, many offer layout planning and 3D renderings for tables, chairs, and booths.

Q3: What’s the best way to ensure safe shipment?

A: Choose professional export packaging (foam + plywood crate + pallet).

Q4: How long does production take?

A: Average 6–8 weeks for standard items; 10–12 weeks for full customization.

🏁 Final Thoughts

Sourcing restaurant supplies furniture directly from a factory is one of the best ways to elevate your restaurant’s quality while controlling your costs. The process demands preparation — but when done right, it ensures your dining space looks beautiful, lasts long, and truly reflects your brand identity.

If you’re seeking a trusted partner with global shipping, full customization, and contract-grade manufacturing, consider Mingmeng Furniture — a professional restaurant furniture factory specializing in bespoke designs for restaurants, cafés, and hotels worldwide.

English

English Zulu

Zulu Igbo

Igbo Yoruba

Yoruba Xhosa

Xhosa Afrikaans

Afrikaans Sesotho

Sesotho Thai

Thai Vietnamese

Vietnamese Indonesian

Indonesian Malay

Malay Lao

Lao Myanmar

Myanmar Khmer

Khmer Turkish

Turkish Hausa

Hausa Portuguese

Portuguese Hindi

Hindi Arabic

Arabic Russian

Russian Japanese

Japanese Chinese

Chinese